When dealing with project management, understanding and calculating the parts per million (PPM) is crucial for evaluating the quality and efficiency of processes. PPM is a measure of the number of defective units or errors per million units produced or processed. It's a key performance indicator (KPI) in many industries, including manufacturing, construction, and software development. In this article, we will delve into the world of PPM, exploring its significance, calculation methods, and how it can be used to improve overall project performance.

Key Points

- Understanding PPM and its importance in quality control and project management

- Step-by-step guide to calculating PPM using different methods

- Applying PPM in various industries to enhance process efficiency and reduce defects

- Integrating PPM with other quality metrics for comprehensive project evaluation

- Best practices for interpreting and utilizing PPM data in decision-making processes

Introduction to PPM and Its Significance

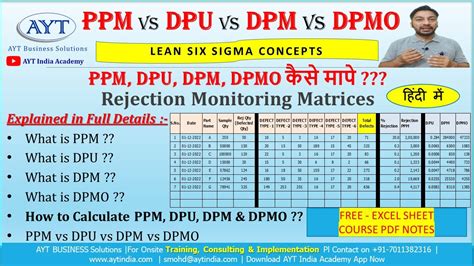

PPM stands for parts per million, which is a statistical measure used to express the concentration of a small quantity of a substance or the frequency of a rare event. In the context of project management and quality control, PPM is used to measure the number of defects or errors per million units produced or processed. This metric is significant because it allows managers and quality control specialists to assess the performance of their processes, identify areas for improvement, and set realistic quality targets.

Calculating PPM: A Step-by-Step Guide

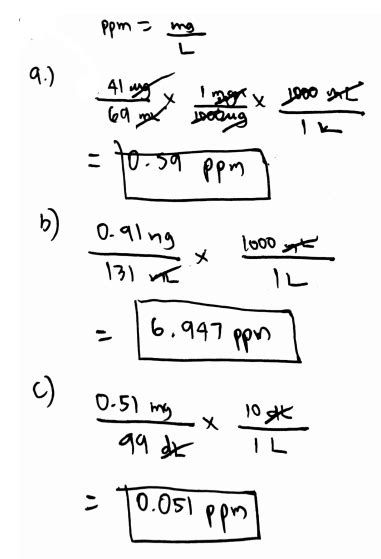

The calculation of PPM involves a simple formula: PPM = (Number of Defects / Total Number of Units) * 1,000,000. For instance, if a manufacturing process produces 100,000 units and there are 25 defects, the PPM would be (25 / 100,000) * 1,000,000 = 250 PPM. This means that there are 250 defects per million units produced. Understanding how to calculate PPM is essential for any project manager or quality control specialist aiming to evaluate and improve process efficiency.

| Category | Formula | Example |

|---|---|---|

| Defect Rate | (Defects / Total Units) * 1,000,000 | (25 / 100,000) * 1,000,000 = 250 PPM |

| Yield Rate | (Good Units / Total Units) * 100 | (99,975 / 100,000) * 100 = 99.975% |

Applying PPM in Various Industries

PPM is not limited to manufacturing; it can be applied in various sectors, including construction, software development, and healthcare. In construction, PPM can be used to measure the number of defects in building projects per million units of work. In software development, it can help track bugs or errors per million lines of code. Understanding how to apply PPM in different contexts requires a deep knowledge of the specific industry’s challenges and quality control standards.

Integrating PPM with Other Quality Metrics

While PPM provides valuable insights into process quality, it is often used in conjunction with other metrics to get a comprehensive view of project performance. These metrics can include defect density, yield rate, and customer satisfaction scores. By integrating PPM with these metrics, managers can develop a more nuanced understanding of their processes and make informed decisions about where to focus improvement efforts.

What is the primary use of PPM in project management?

+The primary use of PPM is to measure the number of defects or errors per million units produced or processed, allowing for the evaluation of process quality and the identification of areas for improvement.

How is PPM calculated?

+PPM is calculated using the formula: PPM = (Number of Defects / Total Number of Units) * 1,000,000.

What does a lower PPM indicate?

+A lower PPM indicates better quality and fewer defects in the process or product.

As we explore the world of PPM and its applications in various industries, it becomes clear that understanding and correctly applying this metric is crucial for improving process efficiency and reducing defects. By mastering the calculation and interpretation of PPM, professionals in project management and quality control can make significant strides in enhancing the quality of their products and services, ultimately contributing to better customer satisfaction and business success.

Meta Description: Learn how to calculate and apply parts per million (PPM) in project management and quality control to evaluate process efficiency and reduce defects.